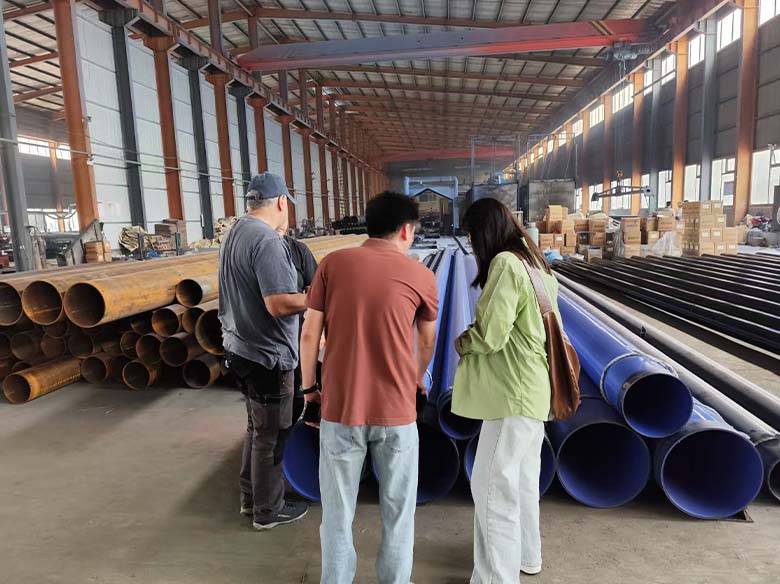

Gianna's important customers visited the factory's production process and inspected the ordered products.

Recently, a delegation from one of our strategic partners visited our company for an inspection. Coordinated and accompanied by Gianna, the foreign trade specialist responsible for the project, the client held a brief yet efficient meeting with our management team. Subsequently, they proceeded to the factory, focusing on an in-depth tour of the production workshops. There, they conducted rigorous on-site inspections and quality certifications for the pre-ordered products: straight seam welded pipes, spiral welded pipes, and shrimp-shaped elbows.

Both parties fully affirmed the achievements of their prior collaboration during the meeting and exchanged views on deepening supply chain cooperation in the high-specification welded pipe sector. Jack Sun, the company's General Manager, stated: “Each visit from our clients serves as the most direct motivation and encouragement for our quality control efforts.”

The visit then shifted to the production floor. Accompanied by the General Manager, Technical Director, and Gianna, the client toured the entire product manufacturing and processing workflow. The client expressed particular interest in the factory's advanced automated welding technology and stable process control capabilities.

In the finished goods inspection area, quality control operations proceeded in an orderly manner. During the inspection process, the client focused on:

FBE-coated products: Verifying coating thickness and adhesion

Shrimp-shaped elbows: Assessing machining precision and surface quality

Longitudinally welded pipes: Validating dimensional tolerances and weld seam quality

Following the inspection, the client expressed high recognition for the products' exceptional quality and the factory's first-class quality control system, specifically noting: “The uniformity and adhesion of the FBE coating exceeded expectations. This batch will be perfectly suited for our high-standard engineering projects.”

This successful on-site inspection has further solidified mutual trust and cooperation between both parties, laying a solid foundation for future large-scale collaboration in the high-end pipeline products sector.